Sustainable / Easy operation / Energy saving Label, package

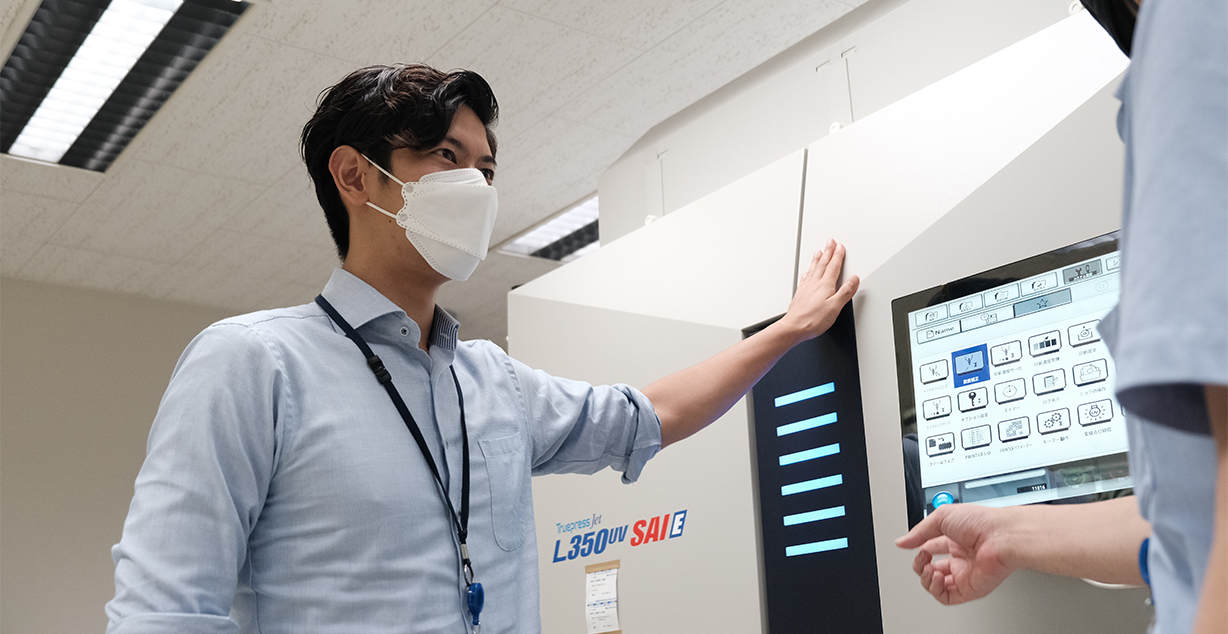

The Truepress Jet L350UV SAI enables easy operation

that overcomes any shortfalls in staff or technical skills.

Try it yourself at the venue!

SCREEN Graphic Solutions Co., Ltd.

Tomoki Kume

Truepress Jet L350UV SAI systems offer three key advantages: 1. they deliver high productivity that enables them to achieve shorter turnarounds for both small and medium lots, 2. they provide a wide color gamut that utilizes orange and blue spot color inks, and 3. they offer high reliability with superior color reproduction even for repeat printing.

All models also feature two recently introduced options that allow them to be used for an even wider range of applications. They are a new high-opacity white mode that significantly improves quality when printing on transparent films and a highly lightfast yellow ink that offers greater resistance to ultraviolet rays. Another major plus is the easy operation these systems provide during color matching and printing. Almost anyone can use them without any particular specialist knowledge after just one or two weeks of training.

Advanced skills are essential for conventional analog printing and operators often need a great deal of time to master registration techniques and color matching processes such as ink mixing. With the Truepress Jet L350UV, on the other hand, the work associated with these skills can be performed from a touch panel. The ability to use functions such as automatic color matching based on colorimetric values has significantly improved efficiency and reduced skill requirements for operators.

As well as shortening turnaround and work times, this advanced operability enables presses to be started up more quickly. It also means printing companies can actively recruit a wider range of personnel, including younger and less experienced operators. With its unique advantages, digital printing is driving major innovations in the way we work.

To illustrate these benefits, we plan to introduce Osaka Sealing Printing Co., Ltd. (OSP), a local company with an advanced operation. OSP has installed a Truepress Jet L350UV+LM following an increase in small lot jobs of 5,000 sheets or less. The company has been extremely pleased with the press’s excellent operability as well as its high color stability and especially its smooth gradations, an area that had presented difficulties with OSP’s previous rotary letterpress system. It mainly uses part-time employees to operate the new Truepress Jet L350UV+LM.

Going forward, OSP intends to further refine its color correction and improve flows of digital data from the design and prepress phases. These steps are part of a concentrated effort to cultivate new demand in the label and seal printing market.

「Our stand at IGAS 2022 will also feature a wide selection of print samples created using systems we are planning to release in the near future. They include our latest water-based inkjet models for, respectively, flexible and paper packages, along with a new analog press for flexible packages and labels.

We warmly invite everyone to visit us and experience the latest solutions we have developed for the label and package printing fields.